Key features

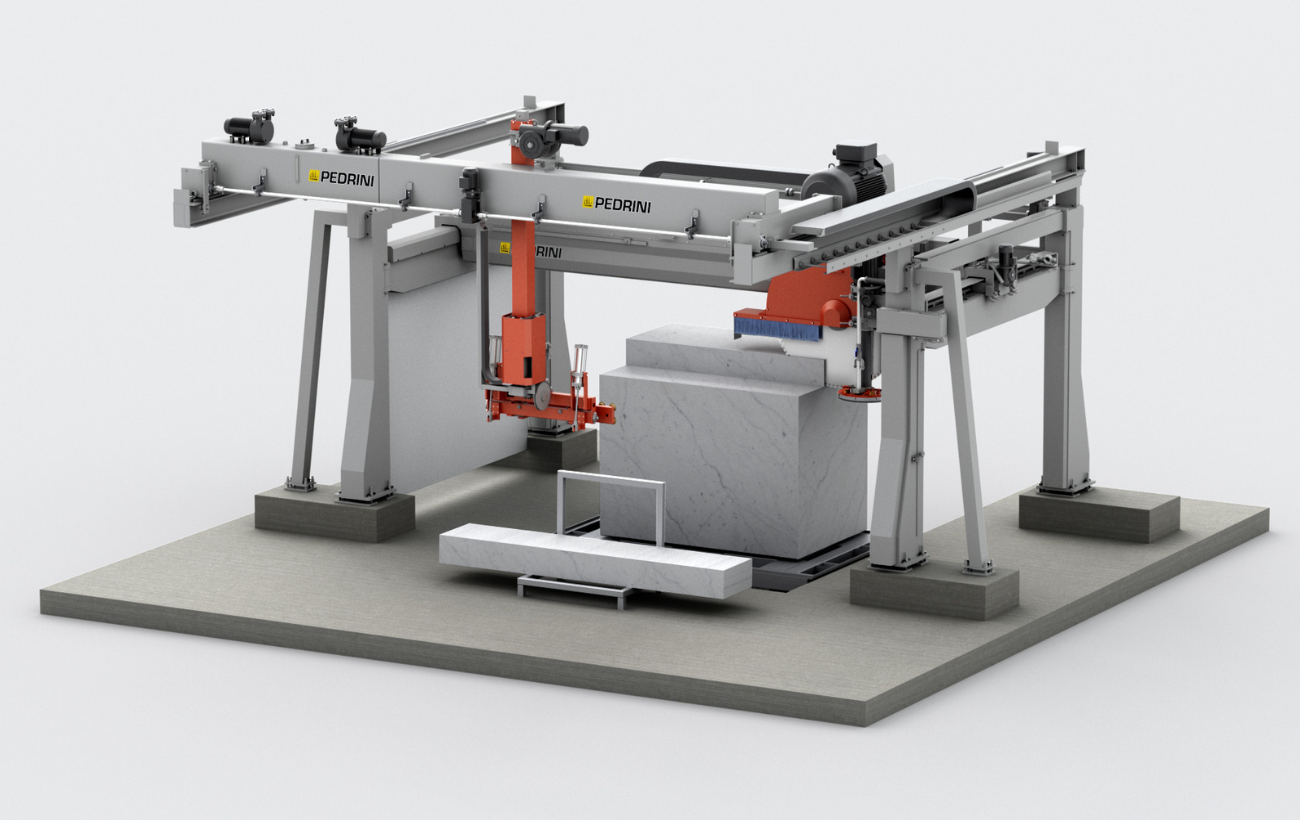

M586

Block cutter for marble

Block cutter for marble

The M586 block cutter is a machine with the traditional 4-column structure for cutting blocks into strips by means of one or more vertical discs and a horizontal disc. It works on stationary block.

The M586 can be offered in different versions that differ in:

The machine can be equipped with automatic or semi-automatic unloaders.

The 4 columns that determine the up and down Y axis movement are fixed to the foundations and are connected on the top by three connecting beams. Two side ribs allow the front side to be open to facilitate the use of the various strips unloading systems and the eventual loading of the block directly into the machine, on the ground level.

The construction technologies of the M586 allow the use of vertical disc motors up to 220 HP, utilizing all the installed power to achieve maximum cutting speeds.

Key features

It manages the cutting of blocks of various sizes and with more or less regular and square shapes

It provides high precision of movements and easy use and maintenance that give a long service life

It works with one or more vertical discs and a horizontal disc and can be set up in different arrangements depending on the work process required

It allows easy and quick change and replacement of diamond discs due to its simple construction and ease of use

Built with a 4-column structure that ensures its stability over time

The M586 block cutter is available in different setups:

Single-disc cutting system

It is composed of one vertical disc and one horizontal disc. It is used when the type of material is variable and a quick change of thickness and height of the lath is required during the cutting cycle

“Scaletta” cutting system

It is composed of two vertical discs of different diameters and a horizontal disc. It is used for fast cutting of formats up to 600 mm

Double disc cutting system

It is composed of two vertical discs of equal diameter and a horizontal disc. It is used for high production of standard formats by allowing for double vertical cutting and double horizontal cutting during cutting and return strokes

Machine components

Strips unloading can be carried out in two ways: semi-automatic unloading with a jib crane and set of suction cups or clamps, automatic unloading with suction cups. In both cases, these are optional equipment

Built in cast iron, it is driven by a gear motor/pinion/rack system. Inside it houses the vertical disc holder spindle with its fittings for the horizontal disc unit

It is composed mainly of a long, large-diameter cylinder fixed on the frontal part of the disc holder trolley

Thank you for your message.

Error

Feel free to contact us for product information, events, customer care and open jobs.