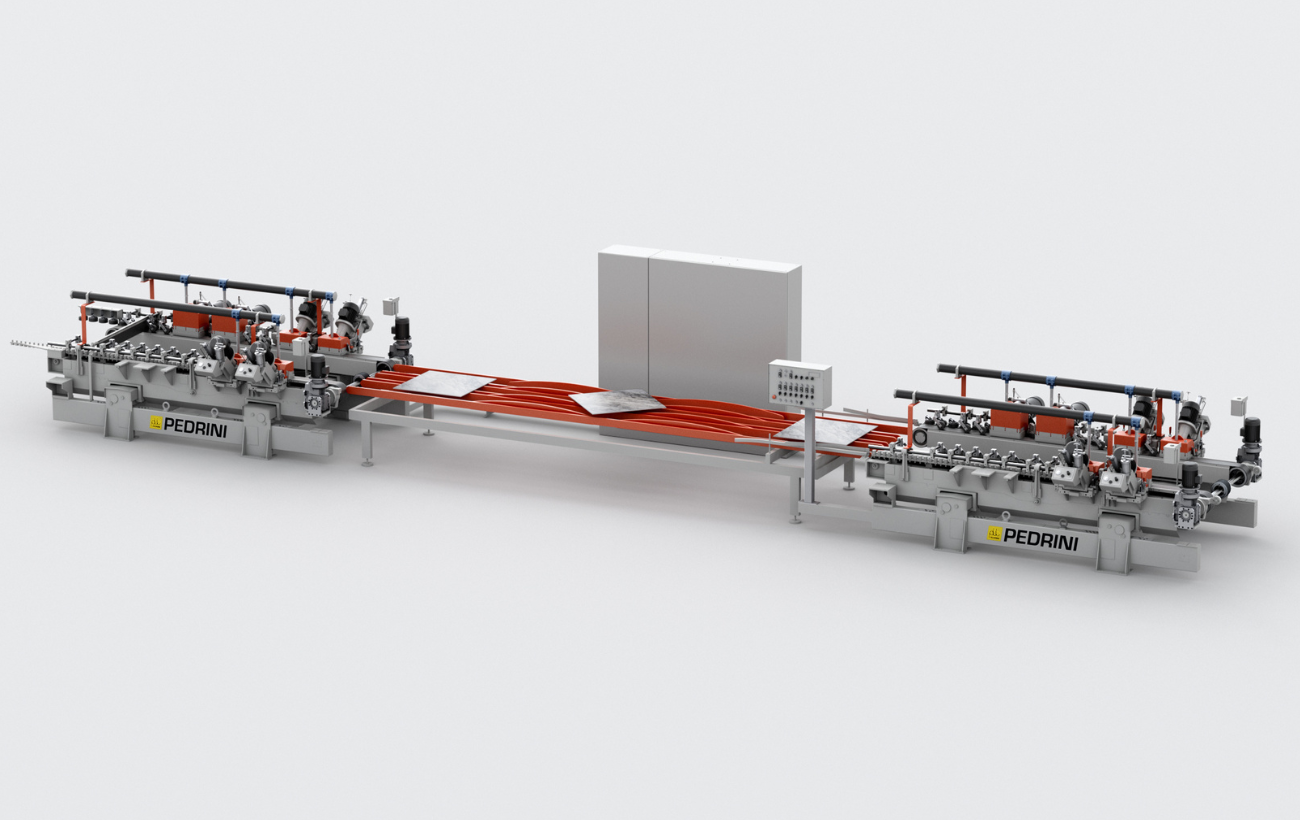

M845

Chamfering machine for marble and granite

Chamfering machine for marble and granite

The M845 chamfering machine performs peripheral finishing of marble and granite tiles and elements. The processing involves the gauging of two consecutive sides by means of diamond tools and the chamfering of the top four edges by means of abrasive tools inclined at 45°.

The M845 chamfering machine is composed of two independent sections connected by a unit for 90° rotation of the gauges.

The M845 is normally included in fully automatic lines for the production of modulmarmo and modulgranito.

It enables precise, high-quality gauging and chamfering due to the considerable distance between gauging and chamfering heads, which allows the two processes to be performed on the same marble tile at different times

It is manufactured in different models to process sizes with widths ranging from 300 mm to 1200 mm

Built with great sturdiness and high-quality components the M845 chamfering machine ensures easy use, precision and productivity in the long term

The M845 chamfering machine is available in three different configurations:

Configurazione lineare

Il gruppo per la rotazione a 90° delle marmette è dotato di dispositivo di esclusione per l’eventuale lavorazione di elementi molto lunghi

Configurazione angolare

Le marmette sono posizionate sulla seconda sezione da un deviatore automatico

Configurazione per rettifica a 3 lati

Questa versione è particolarmente indicata per marmette in granito

Machine components

The calibrating heads are equipped with micrometrical adjustment and automatic locking devices that ensure precision and consistency of the working dimension.

The sturdy side frames that support all the operating elements are equipped with ribs specifically designed to stiffen their structure and to drain water to the machine internal area. The side frames slide transversely driven by two large-diameter ground rods, with interposed precision bushings that eliminate vertical or longitudinal clearance.

The chamfering heads slide along chrome-plated and ground columns with interposition of ball bushings and are equipped with the device for head minimum lift at conveyor belt stop and rapid repositioning at restart.

Thank you for your message.

Error

Feel free to contact us for product information, events, customer care and open jobs.