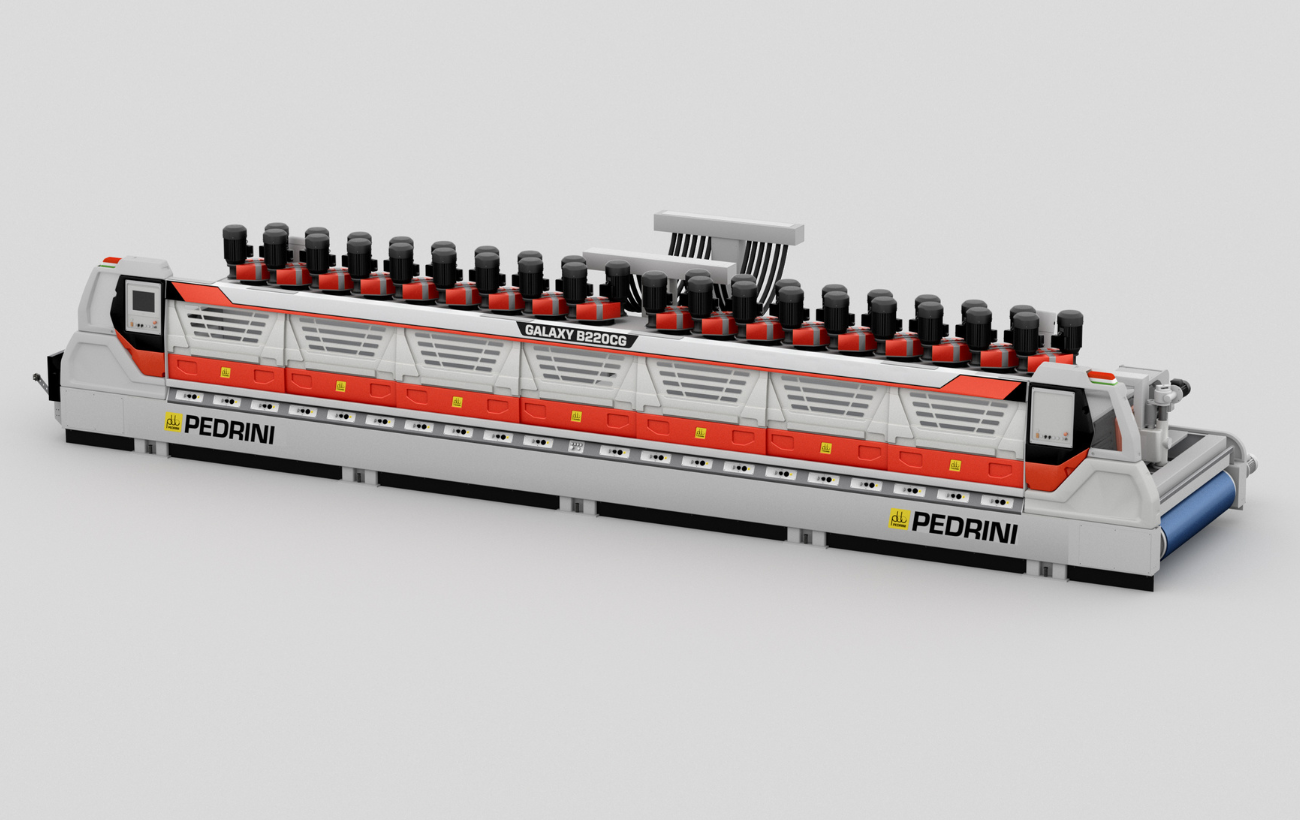

Galaxy B220GX

Polishing machine for granite slabs

Polishing machine for granite slabs

The perfect polishing of granite slabs on industrial scale requires a modern line equipped with state-of-the-art technologies. Pedrini provides the most complete solutions to meet the needs of each customer ensuring high production performance, a very high polishing quality with low operating and maintenance costs.

The polishing machine GALAXY B220GX works with a series of polishing heads equipped with abrasives with increasingly finer grain as the processed material proceeds from the machine entrance to the exit. The polishing heads are mounted on exclusive Rotor spindles patented by Pedrini, characterized a system of counterpressure movements supplied as standard.

GALAXY B220GX, is the result of Pedrini’s technological know-how which, with many years of experience in the business and more than 600 models produced, is a reliable partner, able to answer with highly innovative solutions to the real plant engineering needs of companies that process natural stone.

Galaxy B220GX, the excellence in polishing granite slabs:

Its basement is composed of a heavy normalized steel work single base designed to withstand stress during the processing operation

It can polish all types of granite and quartzite with the utmost precision, preserving the integrity of the slab even with thicknesses as thin as 10 mm

It is designed, manufactured and installed to meet the customer's needs. Each polishing line is set according to the available space and customized through the use of a wide range of options, machines and auxiliary equipment designed to meet any type of production need and automation level.

The slabs polishing machine Galaxy B220GX is available in different versions characterized by the combination of the following parameters:

Number of spindles:

12 – 14 – 16 – 18 – 20 – 22

Spindle equipment:

Spindle with Antishock head with abrasives to process granite

Spindle with Antishock head with marble plate for temporary use

Spindle with marble plate with extension for continuous use

Type of finishing:

Mirror shining polishing

Honing

Machine components

The slab profile reading is detected by a set of 64 optical sensors positioned at the entrance of the machine. In a separate location, an ultrasonic reader measures the slab thickness. This information is useful for managing the spindle vertical strokes and for the abrasive consumption monitoring.

The Aquila head with 5 diamond milling tools is used in the first positions of Galaxy B220GX when pre-honing is needed to remove residual imperfections from previous processing operations.

The Antishock head with 7 tilting abrasive-holder levers is an exclusive Pedrini patent. It uses a special mechanism to obtain tilting and sequential motion of the 7 abrasives. The head accomplishes a perfectly linear contact between abrasives and material, achieving maximum performance.

Rotor is the patented spindle that forms the technological heart of Galaxy B220GX and is made with a one-piece vertical slide assembly with positioning electronically controlled by transducer. It works with a pneumatic counterpressure system.

Thank you for your message.

Error

Feel free to contact us for product information, events, customer care and open jobs.