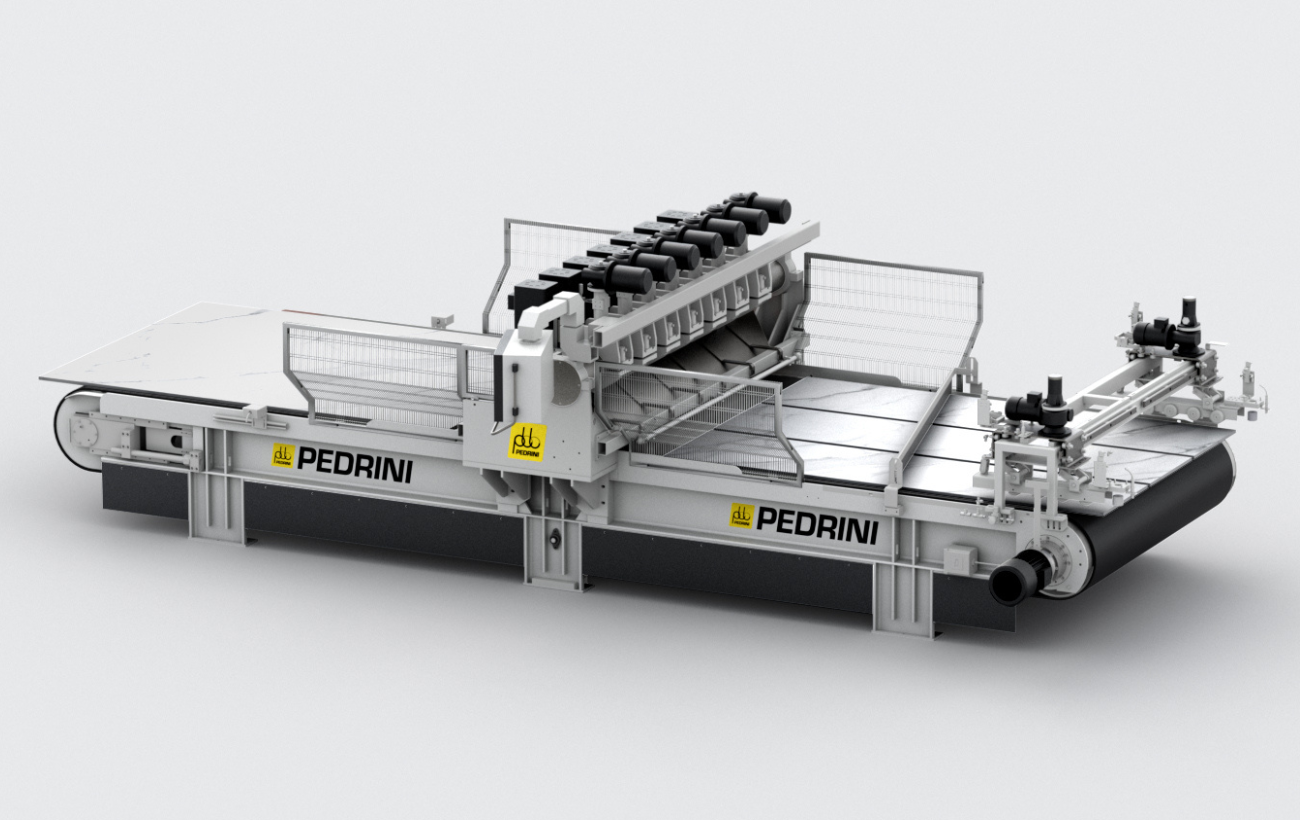

M774

Trimming machine for strips and slabs

Trimming machine for strips and slabs

M744 trimming machines perform continuous longitudinal cutting of marble or granite slabs and strips to produce elements of defined width. Each M744 is equipped with a variable number of discs and with different automation levels and powers depending on production requirements.

The M744LD, M744MD and M744KD trimming machines are used for longitudinal cutting of slabs.

The M744LV trimming machine is used for longitudinal cutting of strips.

Upon request, the trimming machines can be equipped with a Pedrini-patented waste crushing system positioned at the machine exit that allows the waste to be broken into small pieces, facilitating its fall onto the removal conveyor belt.

It can be manufactured in special versions for cutting semi-finished products with sizes other than standard

It comes with side guards to prevent direct access into the cutting area

It works with a fully automatic work cycle that does not require operator intervention

The M744LD, M744LD and M744KD trimming machines, which are particularly suitable for high-production slab cutting lines, are offered with a different number of disc-holder heads depending on the minimum sizes processed and the width of the slabs: 5 - 6 - 7 - 8 discs

The M744LV trimming machine, normally used to trim marble and granite strips no wider than 650 mm, is offered in the following configurations: with 2 discs it allows to trim strips to obtain the final width, with 3 discs it allows to trim and to obtain two strips from a single strip, with 4 discs it allows to trim and to obtain three strips from a single strip

All M744 trimming machines can be optionally equipped with the exclusive cutting system with two aligned discs that allows direct cutting of thicknesses up to 70 mm at twice the speed of standard versions.

Machine components

The cutting group is positioned transversely in the centre of the basement. The disc-holder head assemblies are mounted on a bridge structure formed by a ground and chrome-plated cylindrical beam.

The disc-holder head support is equipped with pre-loaded self-locking that keeps the disc-holder head in the working position.

Upon request, after the cuts have been made, a special Pedrini-patented waste crushing system is mounted at the machine exit to cut the waste into small pieces, facilitating its fall onto the removal conveyor belt.

Thank you for your message.

Error

Feel free to contact us for product information, events, customer care and open jobs.