Calibration line for natural stone slabs: why is it important?

In the natural stone processing industry, the calibrating line plays a crucial role. This process is essential for ensuring the quality and uniformity of finished products, whether they are marble, granite, quartzite, or composite materials. In this article, we will explore what it is used for, why it is so important, and how Pedrini can help you implement the right solution for your needs.

In this article, we will see:

- The purpose of a calibrating line for stone processing

- Why it is important

- Install your calibrating line with Pedrini

The purpose of a calibrating line for stone processing

A calibrating line aims to level the thickness of stone slabs. This process is essential for preparing the slabs for subsequent processing stages, such as polishing or resin treatment. Calibrating is achieved through the use of rotating heads equipped with abrasives or diamond tools, which remove excess material to ensure uniform thickness, planarity, and regularity of the slabs.

The operation of a calibrating line is highly efficient. The slabs are transported on a conveyor roller, passing under the calibrating heads. These heads, adjustable according to the desired thickness, work uniformly on the surface, eliminating any unevenness.

Here is a video showing how a Pedrini calibration line works.

Would you like to know more about how a calibration line works?

Contact us

Why it is important

The importance of a calibrating line in stone processing cannot be underestimated. Some of the main advantages include:

- Thickness uniformity: Calibrating ensures that each slab has the same thickness, which is crucial for the quality of the finished product.

- Productive efficiency: By removing surface imperfections and irregularities, the calibration line facilitates better execution of subsequent processes.

- Quality improvement: A well-executed calibration process reduces the need for additional work, contributing to a better aesthetic result.

Install your calibrating line with Pedrini

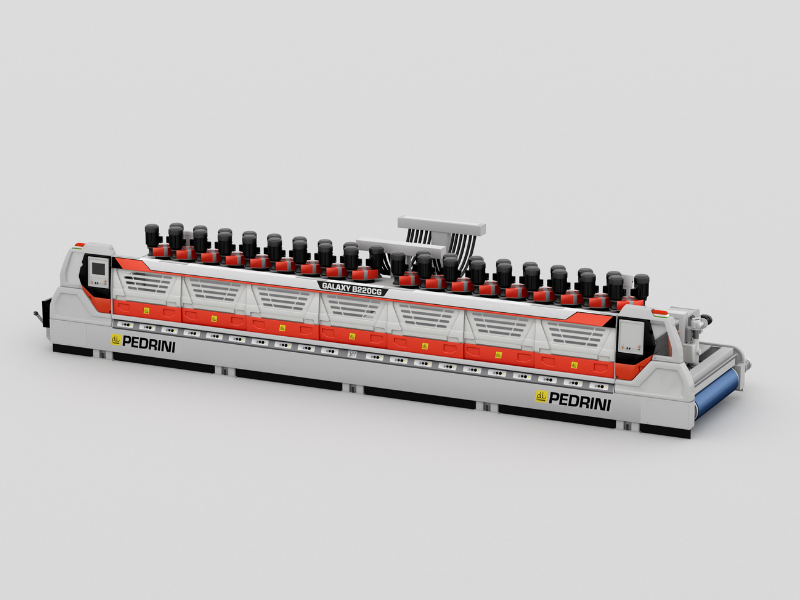

Pedrini is a leading name in the natural stone processing machinery sector, offering advanced solutions for your calibrating line. Among our flagship products are the Spectra and Galaxy B220CG, designed to ensure maximum precision and reliability.

Spectra is a cutting-edge calibrating machine designed to guarantee perfect flatness of natural stone slabs. This machine employs planetary calibration technology with rotating calibrating units, ensuring a homogeneous surface free of irregularities. Its particular configuration is ideal for complex materials and guarantees an excellent finishing result. Spectra stands out for its ability to handle thin thicknesses and delicate materials, offering unparalleled processing precision thanks to the use of specific calibrating heads.

Galaxy B220CG, on the other hand, is equipped with a sequence of operating heads, featuring diamond grinding wheels in the initial positions and oscillating sectors in the subsequent ones. This sequence is particularly effective for removing residual imperfections from previous processes and polishing the surface of the slabs.

The diamond grinding wheel heads, called Aquila, are used to level and calibrate the slabs, while the Antishock heads with oscillating sectors ensure precise and gentle polishing thanks to a perfectly linear contact between abrasives and material. This machine, with its robust structure and advanced control technology, is synonymous with reliability and high-quality production.

Why choose Pedrini? With over 60 years of experience, we provide customized solutions to meet the specific needs of our customers. Our team of experts is available to offer advice and technical support, ensuring optimal installation and start-up.

Choosing Pedrini means choosing quality, innovation, and reliability. Rely on us for your calibrating line!

Contact us

Related news

Thank you for your message.

Error

Do you need more info?

Feel free to contact us for product information, events, customer care and open jobs.