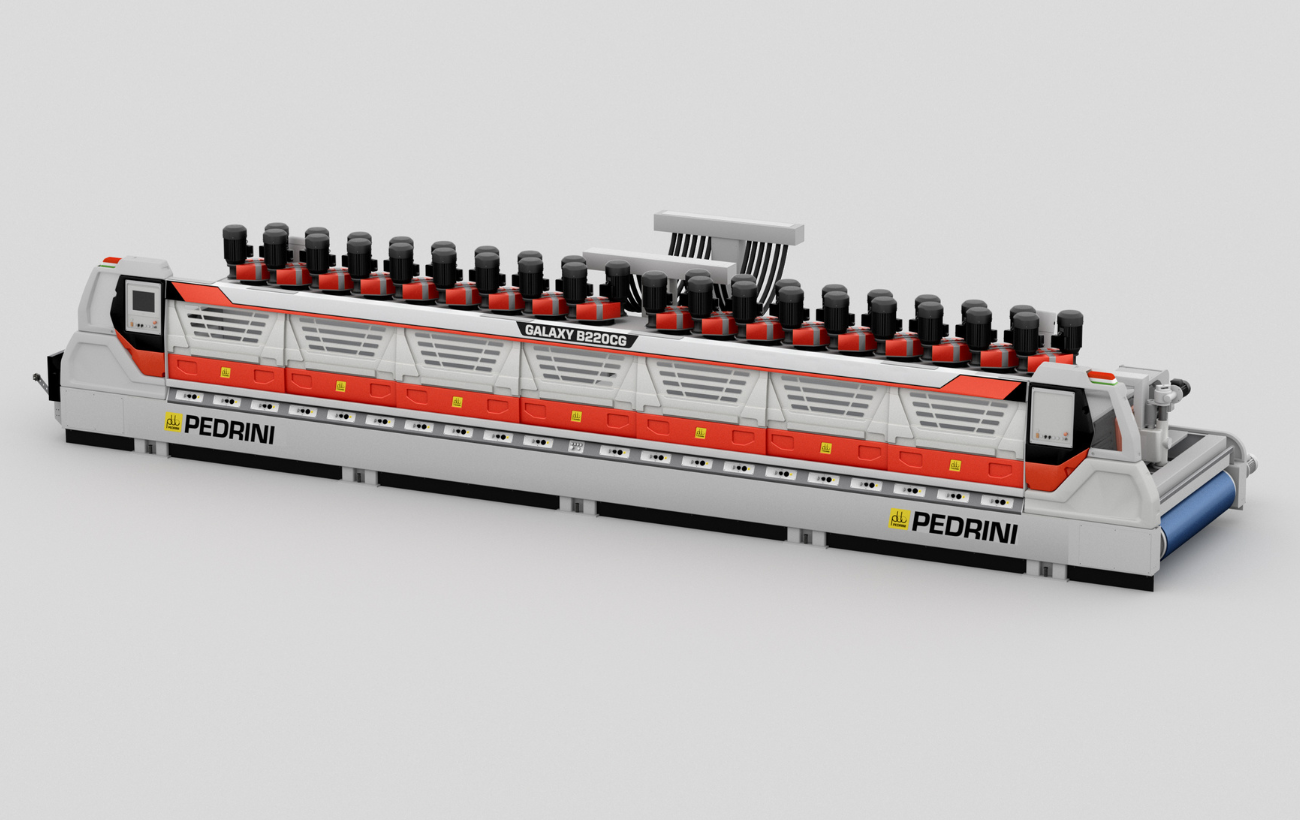

GALAXY B220CG

Calibrating-Honing machine for granite slabs

Calibrating-Honing machine for granite slabs

The hardness of new stone materials, such as quartzites, has made it necessary to adapt polishing lines through the introduction of innovative machines and technologies to obtain a uniform slabs surface.

Pedrini's answer to these new requirements is the GALAXY B220CG calibrating-honing machine. The GALAXY B220CG is equipped with a sequence of operating heads, with diamond milling tools in the first positions and oscillating sectors in the following ones.

This positioning is particularly effective when it is necessary to remove residual imperfections from previous processing operations and to hone the slabs surface.

The main steps to achieve a perfect calibration

The diamond milling heads, called Aquila heads, work in combination with touch probes positioned on the roller bench at the machine entrance. The probes read the slab thickness so that the calibrating machine automatically sets the centesimal adjustment of each head according to the set removal parameter.

The Antishock heads with tilting sectors carry out the honing phase through perfectly linear contact between abrasives and material.

The operating heads are mounted on exclusive ROTOR spindles patented by Pedrini characterised by a system of counterpressure movements supplied as standard.

Its basement is composed of a heavy normalized steel work single base designed to withstand stress during the processing operation.

It is able to process all types of material while maintaining the integrity of the slab even with thicknesses as thin as 10 mm

It is designed to ensure high production performance, a very high honing degree with low operating and maintenance costs

The Galaxy B220CG calibrating-honing machine is available in different versions characterized by the combination of the following parameters:

Number of spindles

16 - 18 - 20 - 22

Sequence of operating heads

6+10 – 6+12 – 6+14 – 8+14

Machine components

The slab thickness reading unit consists of a series of adjustable vertical contact probes that detect the measurement by linear transducers. The reading of the thickness on different areas of the surface allows automatic management of the positioning of the spindles equipped with centesimal adjustment and fitted with Aquila heads.

The Aquila head with 5 tool-holder satellites is used in the first positions of Galaxy B220CG when planarity/calibration of residual imperfections is required. It is equipped with 5 diamond milling tools and gives the slab surface a perfect evenness.

The Antishock head with 7 tilting abrasive holder levers is an exclusive Pedrini patent. It uses a special mechanism to obtain the tilting and sequential motion of the 7 abrasives. The head accomplishes a perfectly linear contact between abrasives and material, ensuring maximum performance

Rotor is the patented spindle that forms the technological heart of Galaxy B220CG and is made with a one-piece vertical slide assembly with positioning electronically controlled by a transducer. It works with a pneumatic counterpressure system.