Create your own granite polishing line with Pedrini

When dealing with the processing of natural stones such as granite, efficiency and quality of polishing are crucial to achieve a valuable end product. A Pedrini granite polishing line ensures excellent production capacity, maximum yield, and polishing quality. We are a leading company in the industry and we provide customized and technologically advanced solutions to meet these needs. Discover them now.

In this article, let's explore:

- What constitutes a Pedrini polishing line

- Why choose Pedrini for your granite polishing line

- How a granite polishing line works

What constitutes a Pedrini polishing line

To achieve a perfect polishing of granite slabs, it is essential to have a modern line equipped with the most advanced technologies.

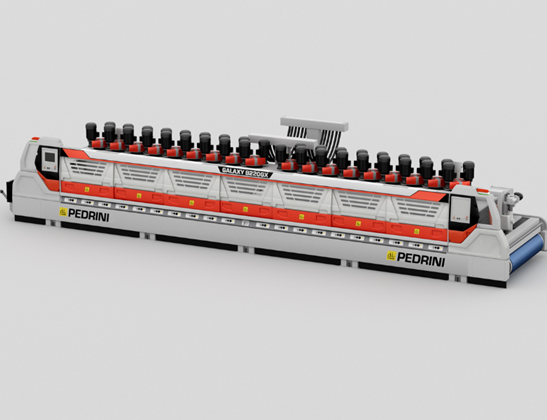

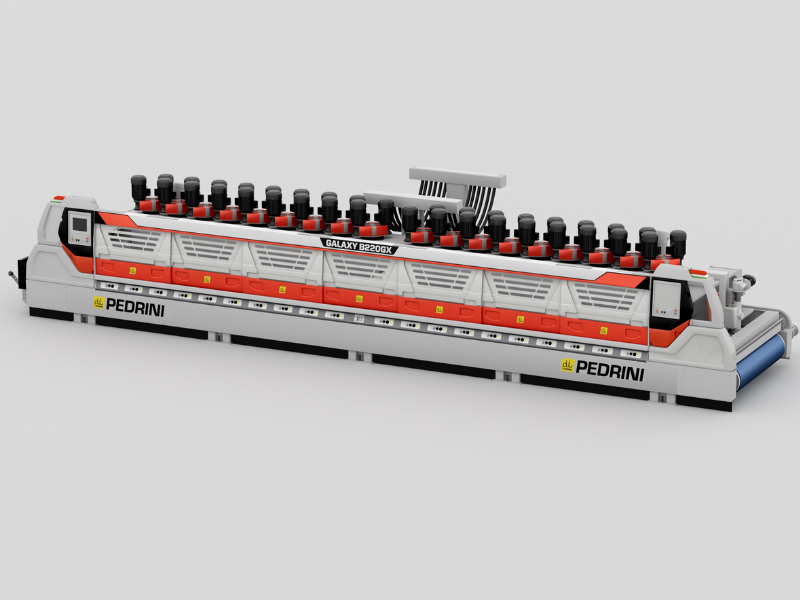

Pedrini meets this requirement by offering comprehensive solutions that ensure high production performance and exceptional polishing quality. At the core of Pedrini's granite polishing lines is the GALAXY slab polishing machine, available in two versions:

Galaxy B220GX-T3:this is a revolutionary slab polishing machine with three mobile beams, designed to enhance the polishing of granite slabs. This machine allows the simultaneous management of slabs of different widths, thanks to the synchronous or independent movement of the beams, reducing downtime. Additionally, the beams optimize the use of tools in various processing stages. Equipped with QuickEase, an intuitive software that makes operation simpler and faster, Galaxy B220GX-T3 stands out for its efficiency, effectiveness, and innovation.

Galaxy B220GX: this machine represents the ideal solution for the industrial polishing of granite slabs, combining innovation and high quality. Equipped with a variable number of polishing heads mounted on patented Rotor spindles, GALAXY B220GX ensures uniform and high-quality polishing. Characterized by solidity, flexibility, and reliability, it is capable of working with precision on various types of granite and quartzite, maintaining the integrity of the slab even at reduced thicknesses.

Why choose Pedrini for your granite polishing line

Pedrini's polishing lines stand out for their ability to ensure efficiency, durability, and superior quality of the finished product. Technological innovation, ease of use, and minimal maintenance are just a few of the advantages that our customers appreciate about our machines.

Our collaboration with Margraf, a renowned leader in the production of high-quality marble and granite slabs with a history dating back to 1906, is an excellent testimony to this.

A loyal Pedrini customer since 2005, the company turned to us once again to develop a complete system for slab production, leading to the creation of a technologically advanced solution.

For the granite polishing phase, Margraf chose our Galaxy GX-T3, our three-beam machine that allows the simultaneous processing of slabs of various sizes, showcasing once again the technological advancement and superior quality that characterize Pedrini.

How a granite polishing line works

A granite polishing line is a complex and sophisticated system designed to transform raw granite slabs into smooth, polished surfaces ready for use. Its operation unfolds as follows:

- The process begins with the loading phase. Pedrini offers various types of loading/unloading machines based on the customer's production needs and the type of material to be polished.

- If necessary, machines for slab calibration can be integrated into the line to ensure uniform thickness.

- The polishing phase follows, where slabs pass through polishing heads that smooth and polish the surface.

- After polishing, the slabs undergo inspection to verify the finish.

Watch this video to see how a Pedrini machine works during the polishing process:

Trust the professionals and create your granite polishing line with Pedrini!

Contact us

Related news

Thank you for your message.

Error

Do you need more info?

Feel free to contact us for product information, events, customer care and open jobs.