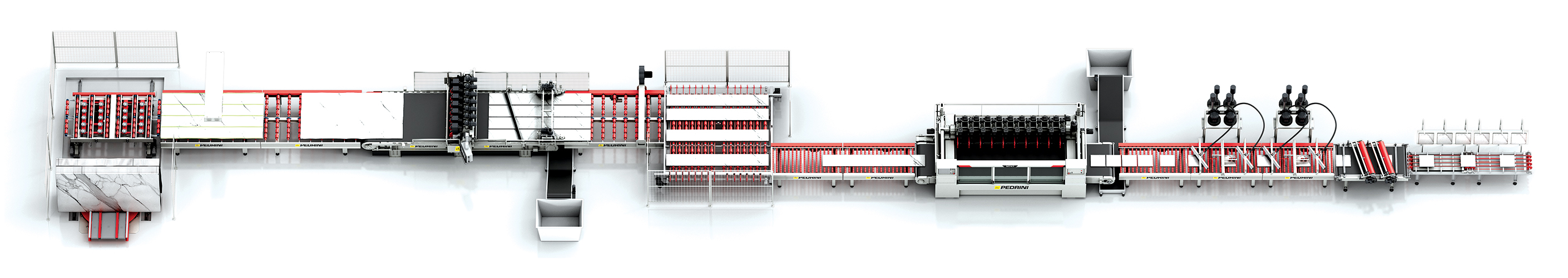

Line components

Description

CUTLINES are high-productivity lines for continuous cutting of marble and granite slabs into rectangular elements with predefined dimensions. The lines are custom-made based on each customer's needs according to various parameters such as the material to be processed, slab thickness, sizes to be produced, production quantity required, level of automation needed, and area available for installation.

CUTLINES allow processing with high production efficiency. Each slab is individually processed and cut according to the customer's needs, its dimensions, and any natural defects in the slab that need to be eliminated.

Line components

Slabs can be loaded either by tilting roller system with the help of a crane or by automatic tilting system.

Find out more

CUTLINEs can be offered in the version equipped with a laser system, which represents the top technology when the cutting of plates is to be combined with the detection of material defects and their exclusion from processing.

The M744 multi-disc trimming machine converts sheets into strip of programmed width. The M744 can be equipped with a number of disc-holding heads (5, 6, 7, 8) depending on the minimum sizes processed and the width of the sheets. A special double-layer rubber belt transports the slab, without deflection or slippage during the cutting process.

Find out more

Diverter switch for connecting and moving the various units.

The multi-disc attesting machine that makes orthogonal cuts of the strips coming from the trimming machine is made with linear conformation, or with transverse conformation.

The two types of machines are characterized by an individual "squaring" alignment system that ensures perfect orthogonality of cross cuts.

Find out more

Finished elements are dried by a group of fans. Then a group of cleaners removes residue from the surface of the material before packaging

The sorting and packing station positioned at the end of the line allows visual sorting and immediate packing.

They enable high-capacity processing

They optimize plate cutting by producing the various formats with recovery in submeasures of the remainder of the multiples and elimination of any natural defects in the material

They can be customized based on customer needs according to different parameters

CUTLINEs can also be offered in versions for special cuts

CUTLINE for cutting special thicknesses

For cutting large thicknesses of granite, the machine with double in-line discs was created, which allows cutting to be done by dividing the effort and consumption over two discs.

CUTLINE for cutting special sizes

Special width versions can be equipped with attesting machines and connection modules that allow processing for cutting filagne up to 1200 mm wide.

Thank you for your message.

Error

Feel free to contact us for product information, events, customer care and open jobs.