Carrara: G.R. Marmi chooses Pedrini for the expansion of its activities

Located in Carrara, G.R. Marmi has been a reference company for the Italian and foreign stone sector for more than 30 years thanks to its deep knowledge of materials and the variety and quality of its offer.

With a view to expanding and upgrading its plants, G.R. Marmi has recently started up two Pedrini lines for marble resining and polishing.

For resining the company chose a compact line with a 20+40 tower, that is 20 levels dedicated to drying/pre-heating and 40 to catalysis. Compact lines are versatile and modular according to the customer's needs and available space. Precisely in order to optimise the use of the area, Pedrini suggested to G.R. Marmi a Butterfly automatic loader equipped with an ad hoc programme to manage the passage of the slab over the slabs support, considerably reducing the space normally dedicated to the loading area.

"This type of passage is not very common in natural stone processing plants, but it became necessary due to the conformation of our building," explained Giuseppe Peselli, CEO of G.R. Marmi. "The Pedrini staff was very helpful and competent in finding the ideal solution and we are very satisfied with it."

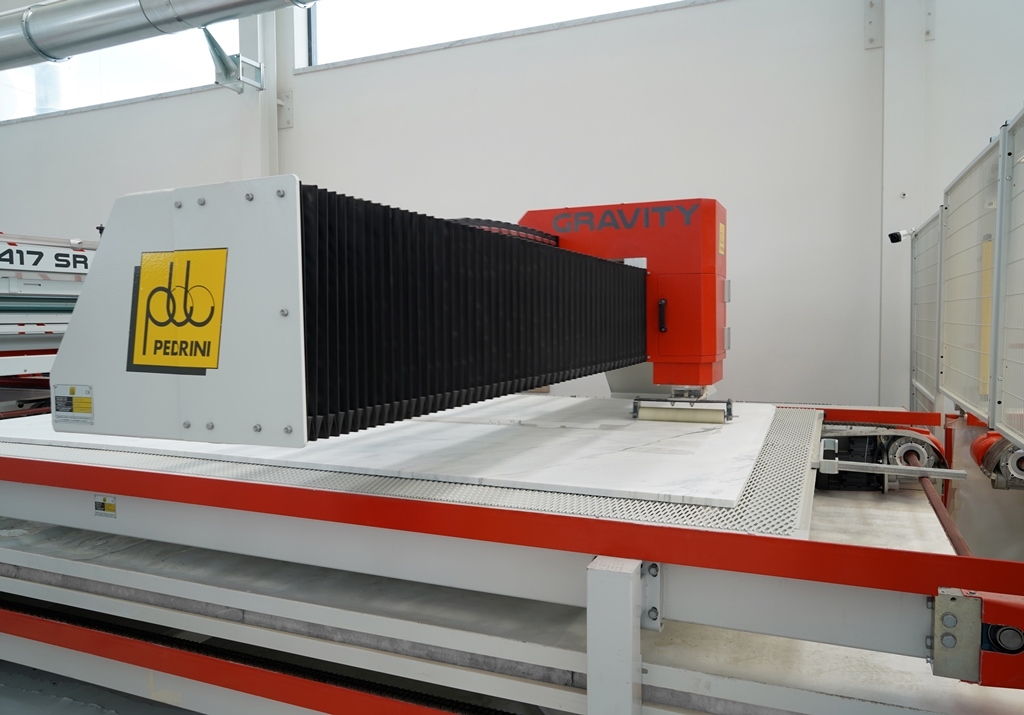

Inside the line there is another innovation recently introduced in the Pedrini range to automatically perform the resin cycle. It’s Gravity, the cartesian robot that acquires the dimensions and shape of the slab, processes the tool path, performs the resin distribution and, as in the case of the line designed for G.R. Marmi, it works in combination with the B417SR automatic net dispenser.

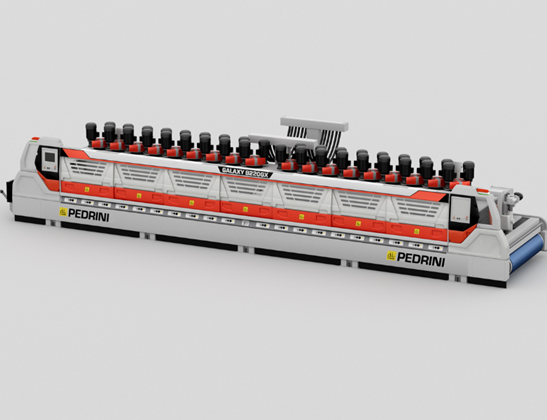

The polishing line consists of the Mantis automatic loader/unloader and an 18-head Galaxy marble slabs polishing machine. The machine has been equipped with the Smart Touch option that allows the strength exerted by each head to be differentiated in different areas of the processed slabs. This function is particularly useful when processing precious materials characterised by zones that vary in consistency.

The entire plant is managed with the Industry 4.0 system, which has been integrated with the customer's management system.