Stone processing machines: the Pedrini range

Processing materials such as marble and granite requires advanced and reliable tools to achieve flawless results. In this regard, Pedrini's stone processing machines offer innovative and reliable solutions, ensuring quality, efficiency, and maximum productivity. Discover our cutting-edge product range designed to optimize your industrial processes.

In this article, we will explore:

- Pedrini's stone processing machines

- Why rely on professional machines for stone processing?

- Choose Pedrini as your stone processing machine manufacturer

Pedrini's stone processing machines

Pedrini is a leading name in the natural stone processing industry, offering cutting-edge technologies for cutting, resining, and polishing marble and granite.

Among the most innovative machines, we have:

Multiwire Jupiter GS230 – A standout model among our stone processing machines. This multiwire machine uses diamond wires to cut granite blocks, ensuring high industrial productivity.

Here’s what you should know about this machine:

- Available in versions with 16 to 108 diamond wires, featuring variable diameters (7.3 mm – 6.3 mm – 5.3 mm – 4.3 mm).

- Simultaneously cuts slabs with thicknesses ranging from 1.2 to 10 cm.

- Hydraulic tensioning system for maximum precision.

- User-friendly interface for automatic cutting programming.

Choose Pedrini for impeccable marble slabs

Our products

Resinline - This complete Pedrini line is designed for the treatment and restoration of marble, granite, and other natural stone slabs, enhancing their mechanical strength and aesthetics through a process that includes loading, drying, resin application, microwave curing, and unloading.

Key benefits of this stone processing solution:

- Greater resin penetration

- Homogeneous resin activation

- Reduced curing time

- Improved aesthetics and minimized material waste

- Energy savings

Learn more about how Resinline works with our video:

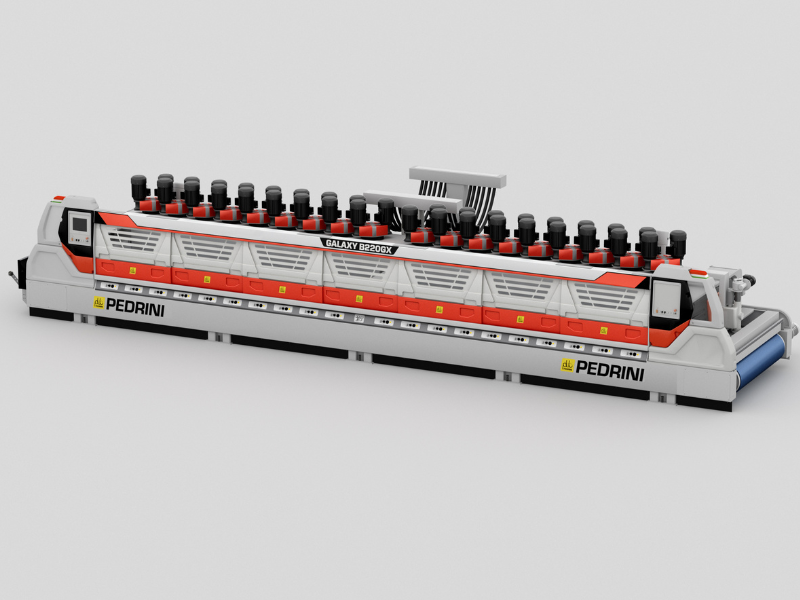

Galaxy B220GX - This high-performance polishing machine ensures top-quality industrial polishing for granite and quartzite slabs.

Key Features:

- A solid structure designed to withstand operational stress.

- Maximum flexibility, even for thin slabs as small as 10 mm.

- Exclusive polishing heads mounted on spindles with a counterpressure system for a flawless finish.

The Galaxy B220GX stands out among our stone processing machines thanks to its high processing speed, superior performance quality, low maintenance, and outstanding production efficiency.

Why rely on professional stone processing machines?

Using professional stone processing machines means optimizing every stage of the production process, enhancing the quality of the final product, and increasing operational efficiency.

Specifically, investing in such a machine means achieving:

- High-precision cuts and finishes for a flawless result

- Minimization of waste and maximum use of raw materials

- Advanced automation that simplifies management and reduces the margin of error

- Energy efficiency and lower maintenance costs for long-term savings

- High-quality standards that enhance competitiveness in the market

To keep up with the demands of the industry, it is essential to invest in reliable and innovative solutions that ensure fast, precise, and sustainable processing.

With Pedrini, you’re in good hands! Contact us and create the perfect solution for your company!

Contact us

Choose Pedrini as your stone processing machine manufacturer

With over 60 years of experience, Pedrini is the benchmark for those seeking reliability, innovation, and performance in natural stone processing. Thanks to our quality and technology-driven approach, we offer cutting-edge solutions that guarantee excellent results.

Relying on Pedrini's professionalism means choosing:

- Continuous Innovation: we constantly invest in research and development to offer increasingly advanced machinery.

- Reliability and support: we are always by your side with specialized technical assistance, both remotely and on-site.

- Field testing: each machine is rigorously tested to ensure optimal performance.

- Automation and optimization: we focus on maximum production efficiency and consistent quality to improve competitiveness and respond quickly and effectively to market demands.

- Customization: we create tailor-made solutions that perfectly fit the specific production needs of each individual customer.

Related news

Thank you for your message.

Error

Do you need more info?

Feel free to contact us for product information, events, customer care and open jobs.